With Müller cutting systems, you can rely on high-performance solutions for the precise and reliable processing of paper webs – ideal for transaction printing, graphic applications and complex production requirements. Whether from a roll or a stack, our systems impress with their flexibility, productivity and easy integration into existing processes.

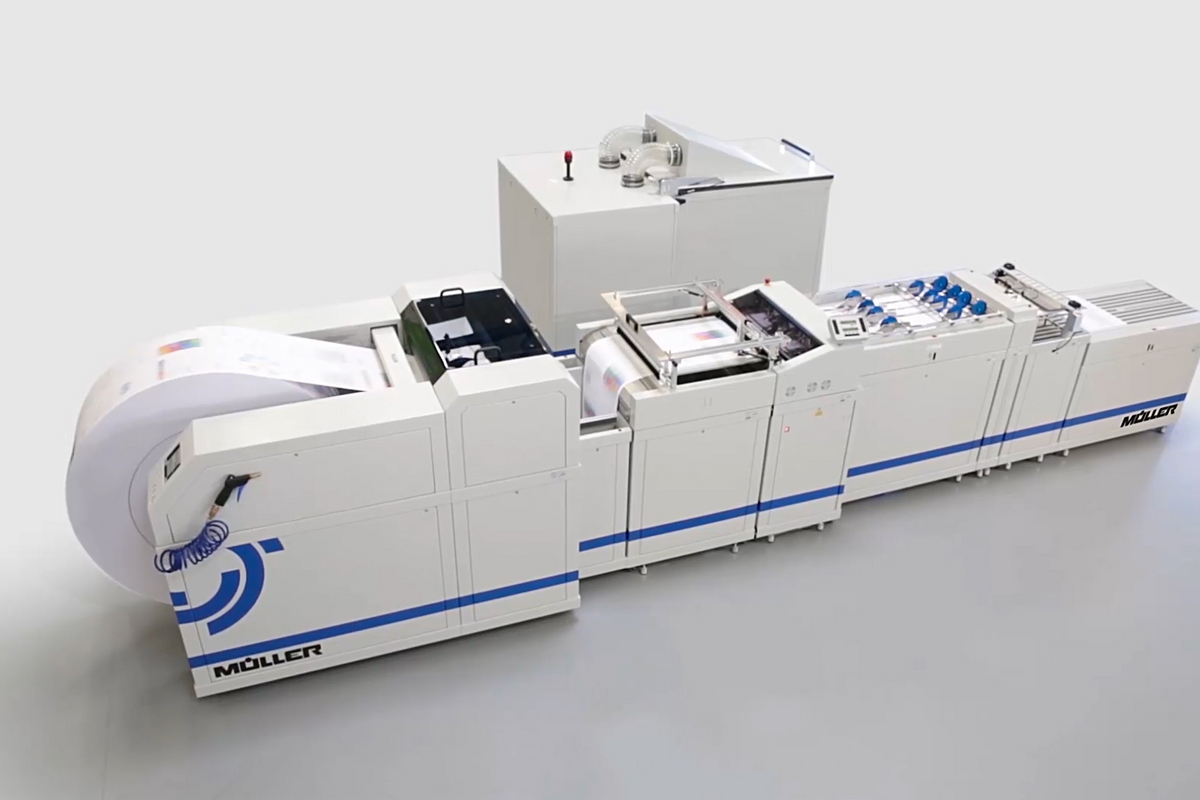

Müller 6700. Variable high-performance cutting system.

The Müller 6700 web cutting system meets the highest requirements in transaction and graphic printing. It is user-friendly, flexible and ideal for complex applications – including Book-of-One. The 22" print width is fully utilised, and variable paper lengths are possible. 1-up and 2-up offset stacks with or without cut-outs maximise efficiency. Whether stand-alone or integrated with web storage, the Müller 6700 impresses with its versatility. Thanks to non-stop stack delivery, even small stacks can be processed online. The system is modularly expandable, e.g. with camera job control, perforation or filing holes.

| Performance |

|

| Paper |

|

| Usage |

|

| Cutter |

|

| Stacker |

|

| Interface |

|

| Options |

|

| * Special dimensions are available on request |

Müller 6500. Dynamic high-performance cutting system.

The Müller 6500 reliably processes print applications at speeds of up to 90 m/min – whether from a roll or stack. It produces formats from 4" to 19.5" for transaction and graphic printing, 1-up or 2-up, with variable trim. In parallel printing, the output is delivered as a book of two, optionally in slalom printing as a book of one – in each case also in offset. The system impresses with its simple operation, high speed and large cut pattern storage. In addition, perforating, punching, grouping and almost continuous group output are possible.

| Performance |

|

| Paper |

|

| Processing |

|

| Cutter |

|

| Stacker |

|

| Interface |

|

| * Special dimensions are available on request |

Müller 6300/6100. Compact continuous cutting systems.

The Müller 6100 and 6300 web cutting systems efficiently process transaction documents such as invoices or notices in all common formats from 4 to 16 inches – whether from rolls or continuous stacks, pinfeed or pinless. With up to 18,000 cycles per hour, single or double cuts trim the paper to the desired format. Up to 100 cutting patterns can be stored and accessed via the display. The systems are flexibly configurable and offer additional functions such as perforation, code reading and grouping. Output is as a hand stack, with/without group separation or interleaved as single sheets.

| Description | With the Müller 6300 cutting system, documents in parallel printing can be processed quickly and reliably. Depending on the desired requirements, the cut paper is then accurately placed on a stack. With an additional delivery belt it is possible to deposit up to six stacks. |

| Paper web width input |

|

| Document width output |

|

| Document length output |

|

| Processing |

|

| Dimension (LxWxH in mm) |

|

| Stack height |

|

| * without edge trim 480 mm / ** 3-up restricted in the formats |

| Description | With the Müller 6300, 2-up paper web in slalom printing – whether from a stack, from a roll or online from the printer – can be easily and quickly processed and merged into a stack. Since the production is almost continuous, the document throughput increases significantly. |

| Paper web width input |

|

| Document length output |

|

| Processing |

|

| Dimension (LxWxH in mm) |

|

| Stacking height |

|

| * without edge trim 480 mm / ** 1-up with conversion possible |

Our Services

Reliable functionality and support after the purchase. Advice before the purchase, support and assistance after the purchase of a Müller system is the be-all and end-all. Efficient support is one of the most important components of the Kern Group. To ensure optimum system availability and productivity, the Kern Group offers a comprehensive and reliable service programme worldwide.

| Performance |

|

| Paper |

|

| Usage |

|

| Cutter |

|

| Stacker |

|

| Interface |

|

| Options |

|

| * Special dimensions are available on request |

| Performance |

|

| Paper |

|

| Processing |

|

| Cutter |

|

| Stacker |

|

| Interface |

|

| * Special dimensions are available on request |

| Description | With the Müller 6300 cutting system, documents in parallel printing can be processed quickly and reliably. Depending on the desired requirements, the cut paper is then accurately placed on a stack. With an additional delivery belt it is possible to deposit up to six stacks. |

| Paper web width input |

|

| Document width output |

|

| Document length output |

|

| Processing |

|

| Dimension (LxWxH in mm) |

|

| Stack height |

|

| * without edge trim 480 mm / ** 3-up restricted in the formats |

| Description | With the Müller 6300, 2-up paper web in slalom printing – whether from a stack, from a roll or online from the printer – can be easily and quickly processed and merged into a stack. Since the production is almost continuous, the document throughput increases significantly. |

| Paper web width input |

|

| Document length output |

|

| Processing |

|

| Dimension (LxWxH in mm) |

|

| Stacking height |

|

| * without edge trim 480 mm / ** 1-up with conversion possible |

Do you need consultation on our systems & solutions?

If you have any questions or input regarding our products and services, please take a few moments to complete the form. We will process your enquiry immediately and look forward to exchanging ideas with you.

Kontakt aufnehmen![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/02-Systeme-Loesungen/M%C3%BCller_Schneidesysteme/Mueller_6700_Schneidesystem.jpg)