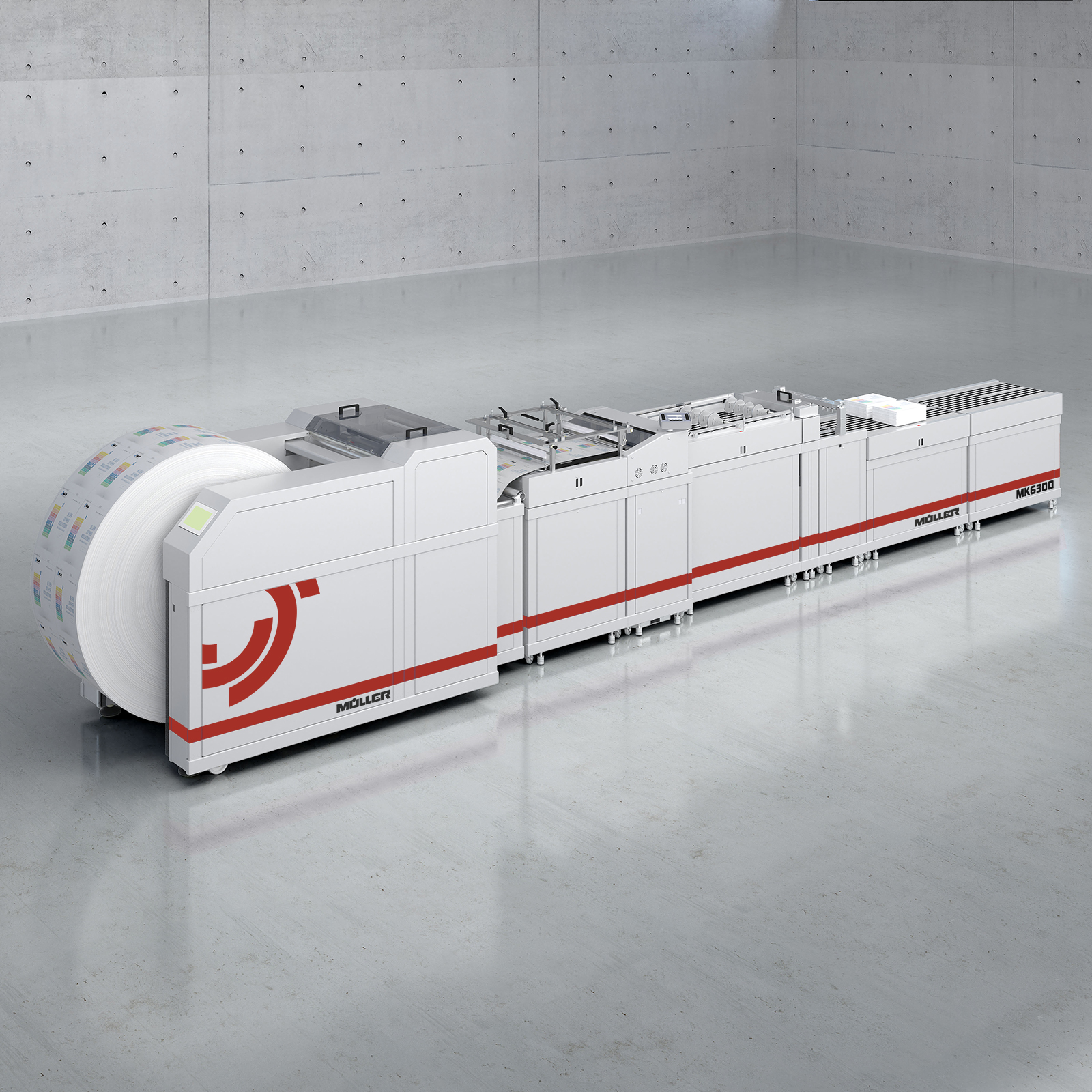

Transactional correspondence such as invoices, reminders or official notifications are processed efficiently and productively by the various configurations of the Müller MK6100 and MK6300 web cutting systems. All common formats from 4 to 16 inches are possible – no matter whether the documents come from a roll or a fanfold stack, whether pinfeed or pinless.

Müller MK6100. Müller MK6300. Compact Web Cutting System.

Single or double cuts trim the gross format to the desired net format at up to 18,000 cycles per hour. The system can handle 100 different cutting patterns thanks to sufficient memory capacity. These can be conveniently stored in the system and called up at any time via the display.

The wide range of possible combinations allows the system to be configured according to the desired requirements. In addition to cutting, the Müller MK6100 and MK6300 enable perforation, code reading and merging of specific groups. At the end of the process, the paper is placed: as a manual stack, stack with or without group separation or as a single sheet in shingled sequence.

Configuration flexibility • customer-specific system design

Flexible processing • pinfeed or pinless, 1-up to 3-up

Ease-of-Use • central display, short set-up times

Printing sequence • slalom or parallel printing

Müller MK6100 - Cut & Stack

Cutting fanfold paper from the stack in 1-up to single sheets is the classic job for the stand-alone cutting system from Müller. This can be done with a single or double cut (cutting out the fold edge). Up to 500 sheets can then be placed on the receiving tray. The system is available both as pure pinfeed and as a combination pinfeed/pinless.

Müller MK6300 - Cut & Stack

With the Müller 6300 cutting system, documents in parallel printing can be processed quickly and reliably. Depending on the desired requirements, the cut paper is then accurately placed on a stack. With an additional delivery belt it is possible to deposit up to six stacks.

Müller MK6300 - Cut & Merge

With the Müller 6300, 2-up paper web in slalom printing – whether from a stack, from a roll or online from the printer – can be easily and quickly processed and merged into a stack. Since the production is almost continuous, the document throughput increases significantly.

| Paper web width Input | Pinfeed: 88 - 500 mm* (3 1/2" - 19 4/6") Pinless: 190 - 500 mm* (7 1/2" - 19 4/6") |

| Document width Output | 88 - 480 mm (3 1/2" - 18") |

| Document length Output | 76 - 330 mm (3" - 13") Alternative: 76 - 610 mm (3" - 24") |

| Processing | 1-up (Typical)** Pinfeed or pinless |

| Dimension with stacking table (LxWxH in mm | Pinfeed: 905 x 760 x 1090 Pinless: 1700 x 760 x 1170 |

| Stacking height | Up to 5 cm |

| * without edge trim 480 mm ** 2-up with reduced output quality possible |

| Paper web width input | Pinfeed: 88 - 500 mm* (3 1/2" - 19 4/6") Pinless: 190 - 500 mm* (7 1/2" - 19 4/6") |

| Document width output | 88 - 480 mm (3 1/2" - 18") |

| Document length output | 85 - 406 mm (3 2/6" - 16") Alternative: 85 - 600 mm (3 2/6² - 26") |

| Processing | 1-up / 2-up / 3-up** Pinfeed or pinless |

| Dimension (LxWxH in mm) | Pinfeed: 970 - 1970 x 760 x 1090 Pinless: 1765 - 2765 x 760 x 1170 |

| Stacking height | Up to 12 cm |

| * without edge trim 480 mm ** 3-up restricted in the formats |

| Paper web width input | Pinfeed: 88 - 500 mm* (3 1/2" - 19 4/6") Pinless: 190 - 500 mm* (7 1/2" - 19 4/6") |

| Document width output | 88 - 480 mm (3 1/2" - 18") |

| Document length output | 85 - 406 mm (3 2/6" - 16") |

| Processing | 1-up / 2-up / 3-up** Pinfeed or pinless |

| Dimension (LxWxH in mm) | Pinfeed: 6360 x 1110 x 1260 Pinless: 7155 x 1110 x 1260 |

| Stacking height | Up to 12 cm |

| * without edge trim 480 mm ** 3-up restricted in the formats |

| Müller MK6300 SM | Müller MK6300 SQ | |

| Paper web width input | 176 - 500 mm* (7" - 19 4/6") | Pinfeed: 88 - 500 mm* (3 1/2" - 19 4/6") Pinless: 190 - 500 mm* (7 1/2" - 19 4/6") |

| Document width output | 88 - 480 mm (3 1/2" - 18") | 102 - 330 mm (4" - 13")** |

| Document length output | 85 - 406 mm (3 2/6" - 16") | 102 - 407 mm (4" - 16")** |

| Processing | 2-up Pinfeed | 1-up / 2-up Pinfeed or pinless |

| Dimension (LxWxH in mm) | 4520 x 760 x 1090 | Pinfeed: 2065 x 3235 x 1110 Pinless: 2860 x 3235 x 1170 |

| Stacking height | Up to 12 cm | Up to 12 cmmmmm |

| * without edge trim 480 mm ** 1-up with conversion possible | * without edge trim 480 mm ** format after the cutter |

| Performance | 12,000 - 18,000 Documents/h in 12" single cut (1-up) Pinless or pinfeed |

| Paper | (40) 60 - 200 (250) g/m² |

| Processing | 1-up to 3-up |

| Cutter | Horizontal slit- and gutter cut vertical slit- and gutter cut (left, right, within the document) Edge trim 28 mm (option up to 60 mm) Recommendation: waste extraction with shredder for pinless-cutter due to endless edge strips Feed rate 1/6", 1/8" or 1/24"; special feed rate for pinfeed |

| Stacker | Stacks up to approx. 1.000 sheets (~ 12cm at 80 g/m²) Group separation (offset) via reading or preset counter |

| Interface | Via Müller-printer-interface |

| * Special dimensions are optionally available on request |

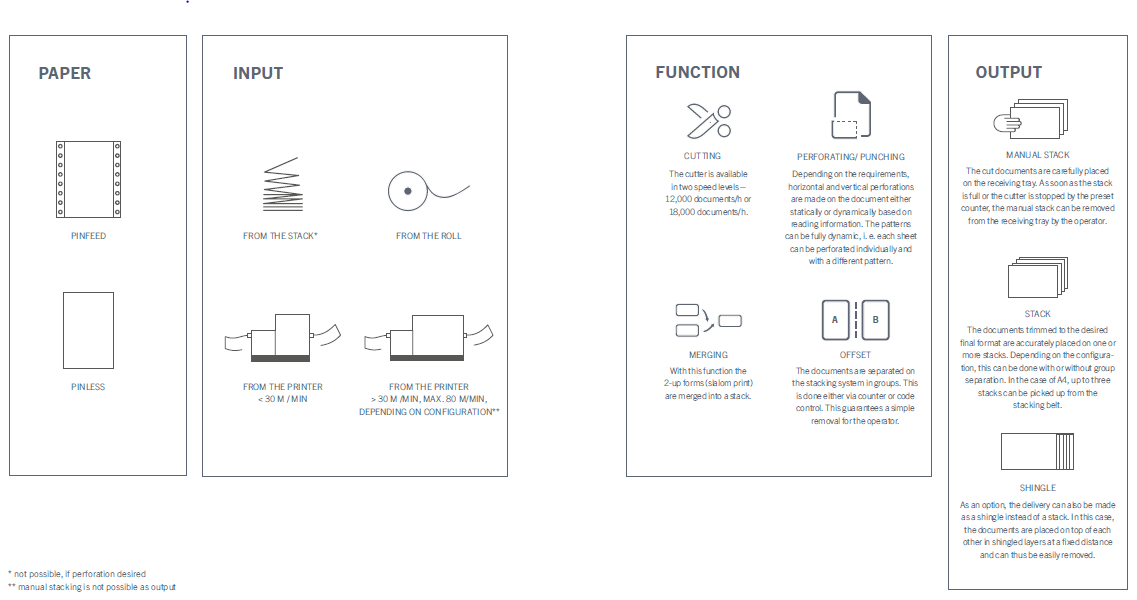

| Step 1: Input | Which paper should be processed? The Müller MK6100 and MK6300 can process both pinfeed and pinless paper. |

| Step 2: Input | How is the paper fed? The paper can be fed into the cutter in various ways – from the fanfold stack, from the roll or online from the printer. Depending on the configuration and customer requirements, the appropriate input device can be selected. |

| Step 3: Function | How should the paper be processed? Depending on the customer requirements, the cutting system can be configured individually. The main function of each cutting system is to trim the document to the desired final format. In addition, the system can be equipped with further functions. Whether this is the perforation or merging of documents or the offset in groups via counter or code control. |

| Step 4: Output | How should the paper output look like? After the paper has been processed, it can be laid down as a stack with or without group separation. |

Our Services

Reliable functionality and support after the purchase. Advice before the purchase, support and assistance after the purchase of a Müller system is the be-all and end-all. Efficient support is one of the most important components of the Kern Group. To ensure optimum system availability and productivity, the Kern Group offers a comprehensive and reliable service programme worldwide.

Do you need consultation on our systems & solutions?

If you have any questions or input regarding our products and services, please take a few moments to complete the form. We will process your enquiry immediately and look forward to exchanging ideas with you.

Get in contact