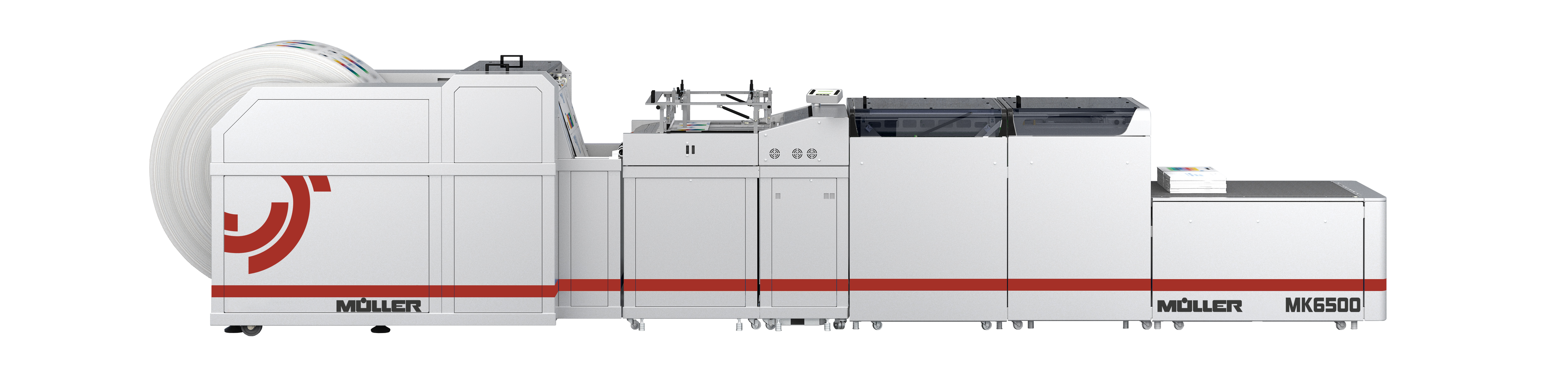

Müller MK6500. Dynamic High-Performance Cutting System.

Regardless of whether the documents come from the stack or from the roll – the web cutting system can produce transactional and graphic arts applications in all common formats from 4" to 19.5". The dynamic high-performance cutting system processes 1-up or 2-up with variable bleed for bleed-off printed products and allows stacking for parallel printing in two stacks (Book of Two) or optionally stacking for slalom printing in one pile (Book of One). With both variants, Off set stacking is possible as standard.

Simple and uncomplicated operation, high running speed and sufficient storage capacity for cutting patterns ensure smooth production. In addition to cutting, the Müller MK6500 also enables perforating, punching and merging of groups, as well as the output of individual groups almost in continuous operation.

| Performance | 12.000 - 18.000 Documents/h in 12" single cut (1-up) pinless oder pinfeed |

| Paper | (40) 60 - 200 (250) g/m² |

| Processing | 1-up up to 2-up |

| Cutter | horizontal slit- and gutter-cut vertical slit- and gutter-cut (left, right, within the document) edge trim 28 mm (option up to 60 mm) recommendation: waste extraction with shredder for pinless-cutter due to endless edge stripes Feed rate 1/6", 1/8" or 1/24" Special speed rate for pinfeed |

| Stacker | Stack up to 2.000 sheets (80 g/m²) group separation (offset) via reading or preset counter |

| Interface | Via Müller-printer-interface |

| * Special dimensions are available on request |

| Overview | With the Müller MK6500, printed products – whether from a stack, roll or online from the printer – are processed quickly and reliably. Each job can be output individually, offset individually in the stack or output when the user-defined stack height is reached. The stacks produced are accurately cut, precisely trimmed, placed at equal distances from each other and ready for further processing or distribution. |

| Paper web width input | Pinfeed: 88 - 500 mm (~ 3" - 20") Pinless: 190 - 500 mm (~ 7" - 20") |

| Paper web width output | 110 - 500 mm (~ 4" - 20") |

| Processing | 1-up / 2-up Pinfeed or Pinless |

| Dimensions (LxWxH in mm) | 4740 x 760 x 1220 mm |

| Stack height | Stack up to 2,000 sheets (80 g/m²) |

| Overview | With the high-performance Müller MK6500 SQ cutting system, documents are processed quickly and easily in slalom printing. The cut documents are then output in a stack (book of one) according to the desired requirements. With the optional web storage, online production takes place almost continuously. This significantly increases the document set. |

| Paper web width input | Pinfeed: 88 - 500 mm (~ 3" - 20") Pinless: 190 - 500 mm (~ 7" - 20") |

| Paper web width output | 100 - 525 mm (~ 4" - 21") |

| Document length output | 110 - 480 mm (~ 4" - 19") |

| Processing | 1-up / 2-up Pinfeed or Pinless |

| Dimensions (LxWxH in mm) | 2860 x 3290 x 1220 mm |

| Stack height | Stack up to 2,000 sheets (80 g/m²) |

Our Services

Reliable functionality and support after the purchase. Advice before the purchase, support and assistance after the purchase of a Müller system is the be-all and end-all. Efficient support is one of the most important components of the Kern Group. To ensure optimum system availability and productivity, the Kern Group offers a comprehensive and reliable service programme worldwide.

Do you need consultation on our systems & solutions?

If you have any questions or input regarding our products and services, please take a few moments to complete the form. We will process your enquiry immediately and look forward to exchanging ideas with you.

Get in contact![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/02-Systeme-Loesungen/M%C3%BCller_Schneidesysteme/Mueller_6500_Schneidesystem.jpg)