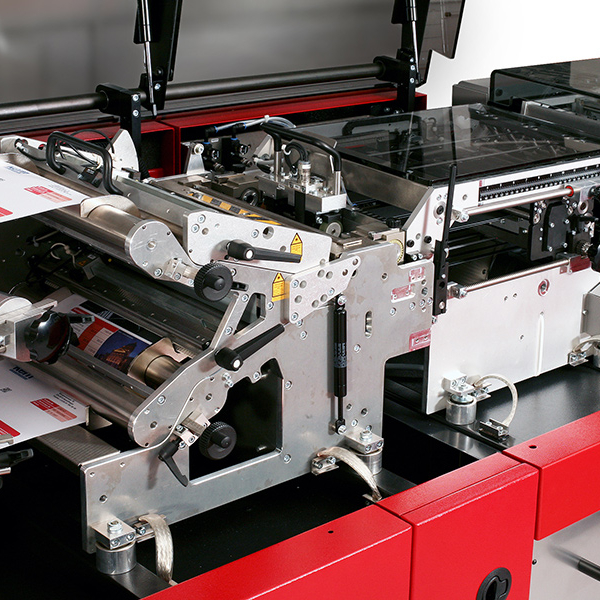

Efficient feed module – the cutter Kern 996 processes a wide variety of applications, offers great flexibility, and boasts high performance efficiency. New with increased cutting performance!

Kern 996 efficient input modules for high-productivity dispatching.

The ergonomic design and the touch screen interface allow fast system access. The automated paper feed accelerates the setup process. The paper flow is clearly visible and easily accessible, so adjustments take little time.

The paper transport is equipped to handle both pinless and pinfed material. All popular standard codes, such as bar code, data matrix, OMR, or OCR, can be processed securely as the module is equipped with the same technology as the Kern 2600, Kern 3600, and Kern 5000 inserting systems.

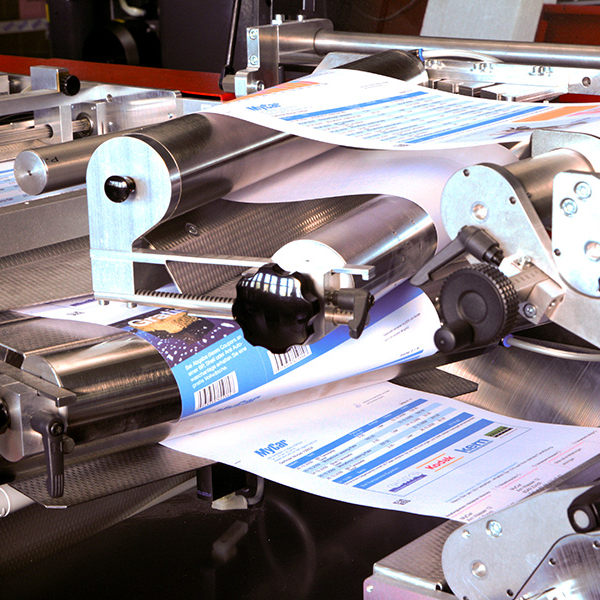

With the Kern 996, non-printed and non-formatted "white" areas (White Paper) between two print jobs or during interruptions are detected and removed. The GT grouping and diversion station diverts white, formatted, and non-formatted documents. The standard diverting bin capacity is 150 sheets (A4) which can be increased using a drop stacker where required. This streamlines processing and increases efficiency.

The optional full page scan reading for the Kern 996 reduces manual system interventions, thus accelerating job processing. The flexible reading system reads various codes from any positions throughout the entire format range. This further increases the job processing reliability and security.

Product Sheet Kern 996

4 MB

Efficient feed module – the cutter Kern 996 processes a wide variety of applications, offers great fl exibility, and boasts high performance effi ciency.

Kern 996basic cutting system

2 MB

The high-performance cutter Kern 996basic offers a strong cutting performance, simple operation and high reliability at an interesting cost-benefit ratio.

Product Sheet Kern White Paper

4 MB

The Kern 996 high-speed cutter automatically detects white paper zones and systematically cuts them out. This optimizes further processing and increases efficiency.

Features Kern 996

- Pure cutting performance at 12"

Max. 36'000 cuts/h with single cut / max. 72'000 Documents/h

Max. 32'000 cuts/h with double cut / max. 64'000 Documents/h - Pure cutting performance at 4"

Max. 55'000 cuts/h with single cut / max. 110'000 Documents/h

Max. 46'000 cuts/h with double cut / max. 92'000 Documents/h - Format width 1-up: 148–295 mm

- Format width 2-up: 296–520 mm

- Document length: 89–407 mm

- Document transport: pinless

- Variable double cut as program cut

- Processes all common standard codes such as barcode, data matrix, OMR or OCR

- Single cut and double cut with no knife change

- Fast, precise, flexible, and easy operation

- Kern mailFactory® compatible

- Compatible with Kern 3600, Kern 2600, and Kern 5000

Our Services

- Personal consultancy on-site

- Requirement analysis, and solution proposal according to customer needs

- Installation by Kern AG

- System integration

- On-site training of your employees

- Reliable support and maintenance during operation

- Customer-oriented service models